Introduction

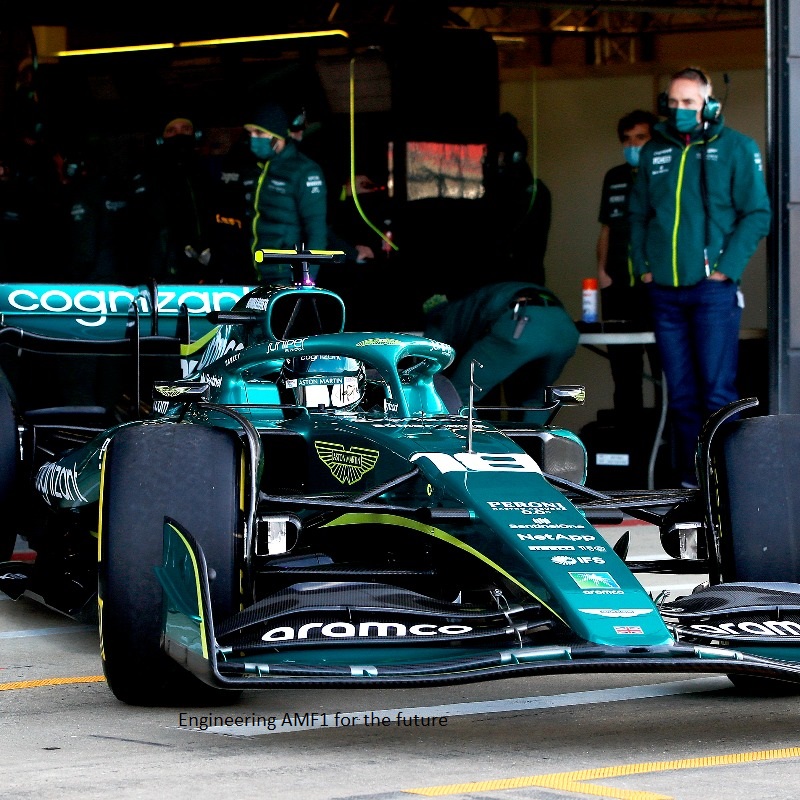

The creation of cutting-edge technologies has played a crucial role in reshaping global economies and industries in the field of advanced manufacturing. The idea of the Adaptive Manufacturing Facility 1 (AMF1) is one such invention that aims to modernize manufacturing processes and take them to new heights. In this essay, we will examine the various aspects of building AMF1 for the future and consider how it might alter the manufacturing environment.

Embracing Technological Advancements

Manufacturing has changed over time from using conventional techniques to embracing modern breakthroughs. Processes can now be more effectively automated, data analyzed, and streamlined thanks to the convergence of these three technologies.

The Rise of Adaptive Manufacturing

The advent of adaptive manufacturing has changed the game. Adaptive manufacturing is responsive and adaptable in Engineering AMF1 for the future contrast to conventional production, which frequently relies on set methods. This idea is demonstrated by AMF1, which incorporates dynamic changes to satisfy changing production demands.

Innovative Design and Architecture

The groundwork for AMF1 is found in its avant-garde architecture and design. To ensure that the facility can adapt to changing needs without requiring major overhauls, engineers are creating a modular structure that enables simple customization and expansion.

Seamless Integration of AI and IoT

Artificial Intelligence (AI) and the Internet of Things (IoT) are the driving forces behind AMF1’s intelligence. AI algorithms analyze real-time data from IoT-connected devices, enabling predictive maintenance, quality control, and optimization of manufacturing processes.

Collaborative Robotics

Humans and robots will work together in collaborative production in the future. Advanced robotics are included into AMF1 to increase productivity while protecting the health and safety of human workers.

Enhanced Efficiency and Productivity

By dynamically adjusting production processes, AMF1 maximizes efficiency and productivity. It eliminates bottlenecks and reduces downtime, leading to increased output without compromising quality.

Minimized Resource Waste Engineering AMF1 for the future

Traditional manufacturing often results in resource waste. AMF1’s adaptive nature optimizes resource utilization, minimizing material waste and energy consumption.

Rapid Prototyping and Innovation

AMF1 uses fast prototyping to speed up innovation. Its quick reconfiguration of manufacturing lines makes it easier to test and improve new product designs.

Technological Integration Challenges

Data security and interoperability are two problems that arise with the fusion of AI, IoT, and robotics. Engineers are diligently building secure systems that protect against online dangers.

Workforce Adaptation

A competent workforce capable of running, maintaining, and optimizing complex systems is needed for the shift to adaptive manufacturing. Programs for training and upskilling are crucial to closing this gap.

Industry 4.0 Redefined

By combining cyber-physical systems with Engineering AMF1 for the future adaptive capabilities, AMF1 exemplifies the ideas behind Industry 4.0. It represents a paradigm shift in the way that businesses approach innovation and production.

Sustainable Manufacturing

The main objective of AMF1 is sustainability. Its resource-saving procedures are in line with international initiatives to lessen environmental effect and encourage environmentally friendly manufacturing.

Conclusion

AMF1 is a shining example of innovation in the dynamic world of advanced manufacturing. Future manufacturing will be effective, flexible, and ecologically sensitive thanks to its adaptability, integration of cutting-edge technologies, and commitment to sustainability. Industries around the world stand to gain from AMF1’s revolutionary potential as engineers continue to enhance and expand its capabilities.

FAQs

What is AMF1?

AMF1 refers to the Adaptive Manufacturing Facility 1, a revolutionary concept in advanced manufacturing that emphasizes adaptability, integration of AI and IoT, and collaboration between humans and robots.

How does AMF1 enhance productivity?

AMF1 dynamically adjusts production processes, eliminating bottlenecks, reducing downtime, and maximizing overall efficiency.

What role does AI play in AMF1?

AI in AMF1 analyzes real-time data from IoT devices, enabling predictive maintenance, quality control, and process optimization.